Untitled Document

© 2015 Miranda Fateri; Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-42147

AM, commonly known as 3D printing, is a technology which is used to build parts directly from CAD data in a layer wise fashion. This process starts with a CAD file of a 3D model which is sliced into various layers to get 2D contours using the inbuilt software of a typical 3D printer. After slicing the layers, each 2D slice is built layer-wise on top of the building platform using different techniques such as melting, binding and extruding process.

AM process is emerging as an industrial revolution in various fields such as Aerospace, Automotive, Architectural and many other industries because it enables fabrication of specialised parts in a simple, cost-effective, and time-efficient manner. However since AM technologies are relatively new and still in development, many new applications are constantly conceived. Regarding this, a novel application of AM processes in fabrication of a mechanical cognitive lock system is studied in this paper.

A cognitive lock is a type of lock that operates and unlocks itself upon the user achieving the solution of the cognitive problem. The cognitive lock itself provides many advantages compared to existing conventional locks since there the key cannot be duplicated or lost and the system cannot be hacked analogously to electronic locks. Biometric locks also have many security concerns as fingerprints can be extracted and duplicated. Additionally these types of lock may put the user in physical harm in order for someone to obtain their various biometric traits, characteristics or tissue. Combination locks are relatively secure and are used in many high security vaults and safes. However, they are only safe as long as the combination is not known.

The present paper pertains to a lock system which is one of the many possible embodiments of the cognitive lock. In this instance, the cognitive lock is materialized through the use of a mechanical disentanglement procedure.

By applying a cognitive lock it is much more difficult to obtain the solution without the user physically being present on-site. This is because the problem must be solved either mechanically or electronically. Thus, a key, combination or password cannot be obtained from the user forcefully. The real owner knowing the solution to the specific lock can unlock it relatively quickly; however, an intruder regardless of expertise will require significantly longer time to determine the solution. The physical presence of the user onsite provides an additional security measure.

The lock and unlocking system proposed in this study functions similar to a mechanical puzzle. The user interface portion of the lock consists of two or more parts that need to be disentangled and/or disassembled in order for the lock to open. The actual lock mechanism can be similar to the existing systems which use various cylinders, rods, etc. to securely close the door or entrance to a vault or room. In the locked state, two or more parts are interconnected and the user must follow a specific procedure to disentangle the interconnected parts in order to open the lock. Disentanglement puzzles could have very limited number of solutions and the number of steps could be copious if required. Similar to disentanglement puzzles, two parts are entangled together and disentanglement is only possible following a limited number of specific movements of the pieces. While the user, knowing the solution can generally disentangle the parts quickly in seconds, finding the correct procedure is time consuming.

In order to improve the security of the device additional possible steps can be taken in order to minimize unwanted access. A timer can be installed in the lock which can limit the unlocking time and the number of attempts to open the lock; exceeding these limits puts the device in a lockdown mode which then requires additional time or procedures before the lock can be opened again.

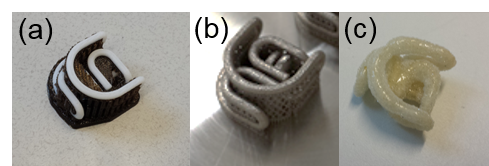

The design of disentanglement locks are limitless and thus if needed unique designs can be made for any individual system. 3D printing of such locks enables the user to fabricate their own lock which means that they do not have to disclose the secret design of the lock to a third-party manufacturer. Additionally compared to conventional subtractive manufacturing and casting processes, 3D printing processes are capable of producing complex parts in low volumes at a reduced manufacturing cost. Besides, 3D printing processes generally do not require the presence of highly trained, high cost technicians. By applying a 3D printing process to fabricate the user interface unlocking mechanism, the specific design can be printed on-site by the end-user and/or manufacturer; furthermore since mechanical disentanglement can be accomplished using countless distinctive designs, the specific design for one user is only known to a limited number of people. In conventional locks, the internals of the lock mechanism are manufactured using conventional methods thus a large number of manufacturing personnel will work on the internal parts of the lock which could potentially lead to the leak of information regarding the vulnerabilities of the lock. 3D printing techniques also make the opportunity to manufacture several parts as an already assembled part which keeps the solution of the puzzle unsolved. Manufacturing of the 3D puzzle can be done using different material but considering this specific security system application as discussed here, the parts shouldn’t be deformable so as to not allow the user to solve the problem by applying physical force and deforming the parts instead of actually solving it. As an example, it is possible to manufacture the mechanical disentanglement lock from ceramic or glass (brittle material) using various AM processes such as SLM, SLS, etc. Once the parts are disentangled, one of many different methods can be applied to detect and verify the disentanglement of the parts such as 3D scanning using a laser or using a camera or using an ultrasonic detector and comparing the results to the original CAD data. Furthermore, for added security, if the individual parts are broken, deformed and/or broken and re-joined in case of forced separation, the system can detect the presence of internal cracks within the disentangled parts using Non-Destructive Testing (NDT) methods for signs of cracks and deformation. An example of a 3D printed disentanglement puzzle from plastic, metal and glass is shown in figure 1.

Figure 1: Additive manufactured disentanglement puzzle out of plastic (a), metal (b), glass (c)

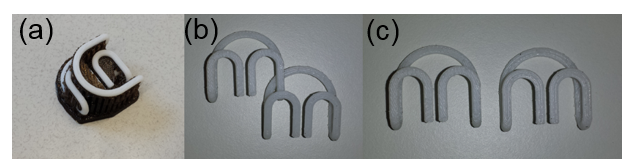

The Additive manufactured disentanglement puzzle including the support structures for plastic and metal and with no supports for glass material which shows the freedom in part orientation are shown in figure one. After removing the supports, as it can be seen in figure 2, the parts are manufactured already assembled as depicted in the middle. The figure 2c shows the two parts separated after solving the puzzle.

Figure 2: Manufactured Part out of plastic with support structure (a), after removing the support (parts are fabricated already assembled) (b), after solving the puzzle (c)

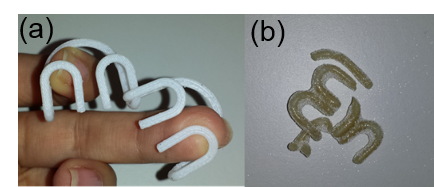

Figure 3 shows the importance of material choice in AM processes for lock system application. As it can be seen in figure 3, parts made out of plastic can be deformed and opened by applying force (Figure 3(a)). Alternatively, if the parts are made out of a brittle material such as ceramics or glass, the parts will break if excessive force is applied (Figure 3(b)) and the unlocking process is halted.

Figure 3: Effect of external force on deformable AM manufactured disentanglement lock (a), brittle disentanglement lock (b)

This method could be used for manufacturing a vault, safe, panic room, or any other enclosure which is secured and closed using a lock.

Cognitive locks, unlike conventional locks, do not have physical keys which can be copied or combinations which can be easily obtained from the user. Even upon forceful retrieval of the solution from the owner, the intruder will require more time to unlock the system compared to the legitimate owner; this can be detected by using electronic systems in the lock. AM can be applied to increase the security level of the lock systems. The lock can be combined with available mechanical and digital lock system methods. Different parts of the lock can be fabricated all at once as an already disassembled parts which brings the tolerance of the fabrication and solution safety in a higher level. The solution to that lock could not be obtained except from the user itself. This is more secure because there are no 3rd party lock manufacturers or operators involved in this. A higher level of security can be obtained by integrating timer or Non-Destructive Testing methods in the locks. It can revolutionize the current locks into more secure and advanced locks, thus providing a very high level of security.

• These 3-D Printed Skeleton Keys Can Pick High-Security Locks in Seconds; http://www.wired.com/2014/08/3d-printed-bump-keys/

• The 3D-printed 'bump keys' that can open almost ANY lock in seconds; http://www.dailymail.co.uk/sciencetech/article-2739879/WATCH-The-3D-printed-bump-keys-open-ANY-lock-seconds.html

• Make a working lock and key; http://www.instructables.com/id/Make-a-working-lock-and-key/

Miranda Fateri, M.Sc.

Fachhochschule Aachen

Goethestraße 1

52064 Aachen

Email:

fateri@fh-aachen.de

WEB:

www.FH-Aachen.de

Prof. Prof. Dr.-Ing. Andreas Gebhardt

Fachhochschule Aachen

Goethestraße 1

52064 Aachen

Email:

gebhardt@fh-aachen.de

WEB:

www.FH-Aachen.de