Untitled Document

© 2013 Gereon Deppe, Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-39586

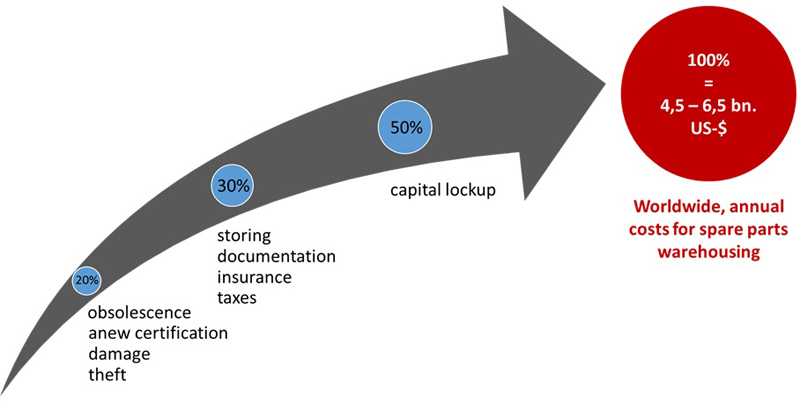

The global competition forces European aerospace companies to optimize their processes and to become more cost efficient. Additionally they have to meet the aeronautics’ high requirements to be flexible and react short-term due to a volatile demand especially in the spare part industry. Only if the aircrafts are ready for operation and airborne they generate turnover and profit. Maintenance, Repair and Overhaul (MRO) providers have to comply with these needs to stay in the market and to satisfy their customers. They have to maximize the serviceability of aircrafts. The necessary flexibility cannot be achieved with conventional manufacturing methods, so extensive warehousing is conducted. Figure 1 shows that the storage of aerospace parts causes worldwide costs of 4.5 to 6.5 billion Euros every year. 50% of the costs are provoked by capital lockup [FrLi09].

Source: Author according to [FrLi09]

Figure 1: Breakdown of the annual costs for warehousing of aerospace parts

Additive Manufacturing (AM) offers high cost saving potential in this area. The technology produces a part layer by layer and thus does not need any tools and is very flexible. Even complex products can be manufactured at nearly no extra costs. This enables the OEMs to design lightweight products which decrease the fuel consumption of aircrafts. Additionally, waste is avoided to the greatest possible extent because the buy-to-fly ratio of AM is usually close to one and thus almost optimal. The flexibility of the production reduces the storage and logistics costs and a lean supply chain is feasible.

Although there are several advantages, AM is currently hardly used. Within this paper different scenarios are developed to describe thinkable exploitations of the technology and to give an outlook how foreseeable developments can be integrated into the existing business models of the market participants.

Today the repair processes need several different process steps. AM can reduce their number with a better near net shape geometry that needs less finishing compared to welding for example. The aim is to get to an automated process with further technology developments so that manual handling is avoided as far as possible.

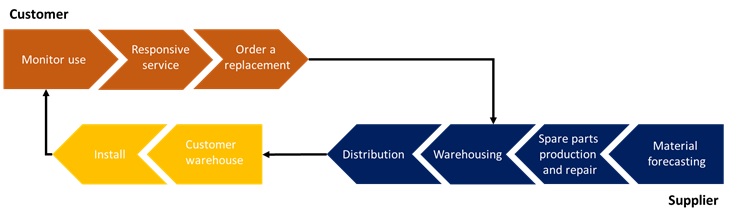

AM does not only affect the production of spare parts but also the supply chain. Nowadays the unpredictable demand is a problem for every spare part supplier and every maintenance organization. The conventional manufacturing process is often not quick enough to produce the required spare parts on demand especially due to the need for tools and the setup time. Therefore a huge amount of spare parts is put in storage to guarantee the delivery in time (cf. figure 2).

Source: Author according to [WHY04]

Figure 2: Conventional demand supply chain for spare parts in aeronautics

Most companies have undertaken enormous efforts and investments to accomplish an effective supply chain management to offer a reliable, fast acting fulfillment. The main goal is to achieve high quality for a low price. However, warehousing hampers to get there. [KPH13]

The specific characteristics of AM offer the chance of being more flexible in manufacturing as well as in fulfilling the demand of the supply chain. It becomes more and more important not just to offer spare parts and their delivery but to focus on a high level of customer value. The key aspect is the operation time of the aircraft and to keep the downtime costs as low as possible. [KPH13]

With regard to EASA formalities there are mainly three different types of organizations to distinguish: The “Part 21/J Design Organization” is allowed to design parts for aircrafts and to prepare Component Maintenance Manuals (CMM). A “Part 21/G Production Organization” can manufacture aerospace parts with regard to the manufacturing instructions given by the Design Organization. “Part 145 Maintenance Organizations” are allowed to maintain aircrafts and to repair aerospace parts with the repair information given by the 21/J Design Organization. A company is not limited to one approval but can have different ones. [Hins12]

The first scenario envisages that AM becomes an additional repair method in existing MRO chains. During the use of a part there is often material worn off and the repair process has to restore the original geometry. The application of material can be done with AM which offers a better accurateness than the conventional welding for example and can manufacture even complex geometries. This shortens the finishing process and the overall number of repair steps. The AM repair of worn and defective parts is novel and much more difficult in comparison to the manufacturing of a completely new part which is currently state-of-the-art for AM. The machine has to know exactly the position of the part. Currently it is necessary for AM that the parts to be repaired have a ground zero where AM can build on. Further developments might enable the direct build up on the existing geometry. This reduces the pre-processing effort as the part does not have to be milled down to a defined level. An important factor is the platform where the part is attached to. It guarantees the fixture of it and dissipates the heat from the part. Future developments could offer the chance to change the size of the build chamber within one system. This shall give the required flexibility to choose the optimal solution for every order and saves the acquisition of machines different sizes.

The second scenario describes the application of AM as a spare part manufacturing method. The aircraft manufacturer put a lot of effort into the transfer to a lean production with conventional manufacturing technologies to be able to react short-term on discrepancies. Nevertheless the overall supply chain is not fast enough to deliver a required spare part within the short time frame that is common in the aerospace sector. Due to the shortfall of tools, AM can start to produce products almost instantly and offers a flexible production for the volatile spare part demand. Especially slow-moving parts that generate high costs during storage can be replaced by additively produced ones. There are some limitations due to the size of the build chamber and the speed or the material choice. But future developments will broaden the scope of application and more parts will be able to be produced by AM. This can be realized in two different ways. On the one hand the OEM can produce the required part and send it to the MRO provider that ordered it. On the other hand it is thinkable that there is a database where the production instructions are saved. After the MRO provider detected the defective part it does not order a new one from the OEM but buys a license to use the manufacturing data from the OEM for an in-house single part production. In this case the supply chain gets considerably leaner and the MRO provider can react much faster. If the MRO provider is not able to produce the spare part by itself or has no capacity there are two options. First, the OEM provides manufacturing capacity by its own and is able to produce the demanded spare part for a MRO provider. Secondly, a service provider can manufacture the part instead.

In contrast to the easy access for the MRO provider, the digital availability put the security of the information at risk. If the data is stolen and illegally distributed on the web, the OEM loses profits of the license purchase and has to face product piracy. For this risk counteractions have to be developed, for example an encryption and a machine-to-machine communication between the database and the AM system with certified devices that are only allowed to use the data.

4. Scenario 3 - AM will become a necessary technology for MRO providers as technology emerges and aircraft manufacturers use AM for their aircraft’s design

The next scenario shows the application of AM for the design of aircrafts. The primes like Boeing and Airbus can use AM parts to enhance the performance of their aircrafts. To reduce the aircraft’s weight in order to save fuel, lightweight parts are required as fuel efficiency is a major criterion when airlines purchase new aircrafts [Boei12]. The assembly effort can be reduced, too, because AM can build assembled products or an integrated assembly support. The typical low scale volume production is another reason to use AM as it does not need to manufacture in batches [Gebh07]. Furthermore parts can be optimized for their application without the need to be suitable for conventional production. The reliability is going to be higher for the function-optimized parts. The complexity of parts can increase without entailing higher costs for the production. Further developments of the accurateness will lead to just a minimum amount of finishing so parts can be produced just in time. Warehousing can then be significantly reduced while the supply chain gets more agile. So the primes have a higher flexibility within their production as they often have to decrease and increase the in- and output due to a volatile order receipt and counter-orders. The introduction of AM by the primes has the positive side effect that the technology is officially approved and is integrated in the Component Maintenance Manuals (CMM). Then the MRO providers latest can use the technology to repair defective parts and gain all the advantages that come along with it.

The last scenario describes an advanced application of AM in the aerospace. The current processes to repair a defective part are complex and the supply chain is long. A well-developed AM technology can significantly simplify the described proceeding. It is then possible to manufacture spare parts at the airport where the aircraft alights. Together with a reliable part monitoring and usage based lifetime prediction, the part can be produced with AM while the aircraft is still in the air. Therefore the aircraft’s monitoring system has to become more accurate as it has to detect not just the system that failed but also the exact part that caused the incidence. As mentioned before the costs for warehousing are extremely high in the aerospace industry. Due to a flexible on-time manufacturing, warehousing and shipping expenses could be significantly reduced. Thus costs could decrease considerably and the MRO provider could become much more competitive

To reach that goal the AM technology has to be improved in different areas. First of all it has to become much faster in the production of parts while the build chamber has to become bigger at the same time to manufacture large parts in an acceptable period of time. Furthermore the surface and dimensional accuracy has to become better to reduce finishing to a minimum. More materials are necessary to produce parts that fit specific requirements. Therefore a flexible material processing and perhaps a multi material production are inevitable. To manufacture spare parts at all there has to be a database containing the manufacturing data provided by the OEMs and primes where a license can be purchased to build the part additively at the airport.

Up to now the introduction of AM in the aerospace industry is hesitant. There are still some problems that have to be solved but nevertheless there are already applications possible. One major problem is still the certification of the technology as the process is not perfectly stable and there are many influence factors that affect the part quality. The build chamber size and the speed of the manufacturing process are both not at the level that they need to have for a full application in aeronautics. Nevertheless some of the tier 1 suppliers already research applications and try to bring the technology to the market within the next years to be able to profit by the advantages of AM.

The currently existing business models will be influenced in the future by the use of AM because the technology offers new potentials. The shape of the change can differ enormously. It depends on the development of the additive technology within the next years. The faster the technology will develop the more opportunities are going to be provided. The question is to what extent the “Part 21/J Design Organizations” will make use of the technology. One can assume that the better the technology, the higher is the chance that the technology is used more often. This is the case especially if improvements in the areas of surface quality, dimensional accuracy and process control will be achieved. Thus the technology can be used for a much broader area of applications and can cause further changes of the existing business models.

The work presented in this paper has received funding from the European Union’s Seventh Framework Programme (FP7/2007-2013) under grant agreement n°605779

[Boei12] Boeing (2012): Current Market Outlook 2012-2031. Hg. v. Market Analysis. Boeing. Seattle, WA. Online available at: http://www.boeing.com/commercial/cmo/pdf/Boeing_Current_Market_Outlook_2012.pdf, checked 21.10.2013

[FrLi09] Friedrich, Sebastian; List, Stefanie (2009): Supply Chain Kooperation in der Ersatzteillogistik für die Luftfahrt (English: Supply chain cooperation in the aeronautics‘ spare part logistics). In: Stefan Voß, Julia Pahl und Silvia Schwarze (Hg.): Logistik Management. Heidelberg: Physica-Verlag HD, S. 55–75

[Gebh07] Gebhardt, Andreas (2007): Generative Fertigungsverfahren. Rapid prototyping - rapid tooling - rapid manufacturing. 3. Aufl. München: Hanser

[Hins12] Hinsch, Martin (2012): Industrielles Luftfahrtmanagement (English: Industrial aviation management), 2nd edition Berlin/Heidelberg: Springer Verlag

[KPH13] Khajavi, Siavash H.; Partanen, Jouni; Holmström, Jan (2013): Additive manufacturing in the spare parts supply chain. In: Computers in Industry. DOI: 10.1016/j.compind.2013.07.008

[SGF+08] Spiegel, Hildburg; Götte, Sascha; Friehmelt, Holger (2008): Partnership Supply Chain in der Luftfahrt (English: Partnership supply chain in the aerospace sector). In: Partnership supply chain in der Luftfahrt

[WHY04] Walter, Manfred; Holmström, Jan; Yrjölä, Hannu (2004): Rapid manufacturing and its impact on supply chain management. Helsinki University of Technology, Helsinki

M. Sc. Gereon Deppe

Universitaet Paderborn

C.I.K. / DMRC

Pohlweg 47-49

33098 Paderborn

E-Mail:

deppe@cik.upb.de

Web:

www.cik.upb.de

Univ.-Prof. Dr.-Ing. Rainer Koch

Universitaet Paderborn

C.I.K.

Pohlweg 47-49

33098 Paderborn

E-Mail:

r.koch@cik.upb.de

Web:

www.cik.upb.de