Untitled Document

© 2013 Andreas Gebhardt; Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-35626

Additive manufacturing (AM), also known as Rapid Manufacturing (RM) and Rapid Prototyping (RP), works by building up solid objects layer by layer in a manner similar to a 2D printer with the "printed" layers stacked on top of each other. As such, 3D printing is a general name which can cover the various AM technologies and as such will be used in this paper (1).

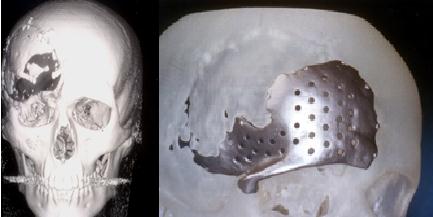

A new technology or invention can be evaluated by considering its applications and positive influence on human life and society. Regarding this, “Maslow's hierarchy of needs” is a good foundation for evaluation. In this pyramid all of the human needs are defined and grouped based on their priority according to the basic necessities and quality of life.

Maslow uses the terms Physiological, Safety, Belongingness and Love, Esteem, and Self-actualization to describe the needs that humans generally desire. Maslow's hierarchy of needs is often portrayed in the shape of a pyramid, with the largest and most fundamental levels of needs at the bottom and the need for self-actualization at the top.

Figure 1: Maslow's Hierarchy of Needs (2)

Starting with base of the pyramid, primitive physiological human needs must be satisfied. Food and shelter are two essential needs in this group which have been addressed by 3D printing research.

Food is one of fundamental ingredients of life which is at the base of the pyramid of human needs. Bringing the food industry to the digital age is one of the essential and revolutionary applications of 3D printing. Applying this technology enables fast automated and repeatable processes, freedom in design, as well as allowing large and easy variability of the cooking process which can be customized for each region or individual. Using robotic layer based food printing systems allows the recipe of the food to be digitized and saved in order to prepare very repeatable and high quality dishes without any margin for operator error. Also, the shape and decoration of the food can be individualized based on the customer or the occasion.

A company called Choc Edge is currently marketing "the world's first commercial 3D chocolate printer", the Choc Creator. It uses a nozzle to dispense molten chocolate into any pattern and shape. While the $3,500 price might be expensive for home use, it can prove to be very successful for niche shops tailoring to specific customers or events (3).

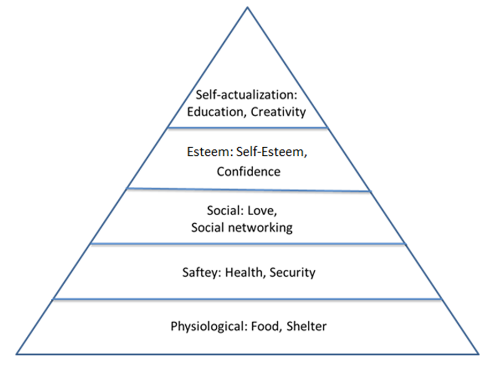

Figure 2: 3D printing of chocolate (3)

Researches in university of Cornell have demonstrated new materials suitable for baking, broiling and frying for use with food 3D printers. As it is shown in the figure printed objects were deep fried and retained their shape with minimal loss of detail due to deep frying.

Figure 3: 3D printing of food, before being frying (left), after frying (right) (4)

MIT’s Cornucopia program is also working on specialized 3D printers for the food industry and so far has designed four prototypes. The digital Chocolatier allows for the design of chocolate and candies which even has a "carousel" of ingredients, and the digital fabricator combines selected ingredients and turns them into "flavors and textures that would be completely unimaginable with other cooking techniques."

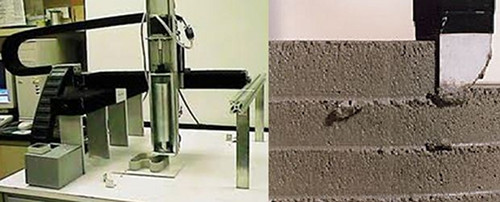

Shelter is another basic human necessity which can be an interesting application for 3D printing. The building industry is one of the last remaining fields where human labor and skills are the norm and mass manufacturing techniques and robots are considered science fiction. Given that a large portion of world population is without permanent shelter or food, it would be logical to think that these basic necessities should be top priority for robotized manufacturing techniques yet both the construction and food industries remain labor intensive. Conventional building methods are hazardous, time consuming, and expensive; 3D printing of buildings can enable automated creation of variety of buildings quickly and efficiently. This technology has been invented and developed in the University of Southern California. A scale down version of a house 3D printing machine is shown in figure 4.

Figure 4: Scaled down version of house 3D printing machine (left), 3D printed concrete layers (right) (5)

The technology can be used for a variety of housing projects with application in custom luxury designer homes, large scale development projects, to temporary housing projects. This technology could also enable engineers to design and build stiffer and safer geometries for houses i.e. Dom geometries which are typically very labor intensive and difficult to be constructed.

Figure 5: Safe and stiff construction design appropriate for earthquake regions, Dom shape 3D printed parts (5)

This technology can also help engineers to rebuild and restore old heritage designs quickly yet accurately.

Figure 6: Sagrada family, Gaudi design (left), 3D printed object similar to the Gaudi design (6)

It would also be possible to build individual intricate artistic designs never before possible while giving the architects freedom of design without sacrificing structural rigidity or safety of workers.

Figure 7: 3D printing of complicated geometries (6)

The Second stage of Maslow’s pyramid includes safety and security needs. Health and social communication are two factors which are reviewed in this section due to their importance in human life.

While much effort is put forth by individuals, societies, and businesses to improve our physical health, an ideal health is very subjective and could depend on location and vary over time. However, it can be said that the absence of sickness, specially, chronic illnesses is a requisite for good health. Illnesses, accidents, and aging deteriorate the body's or a specific organ's condition. Organ transplants have been successfully conducted for the past century; however, there has always been a shortage of donors or an inability to find a match between the donor and recipient in time. 3D printing is an advanced recent technology in this field which can be a revolutionary alternative with a variety of applications in the transplant and healthcare industry in general. 3D printing research is investigated in various fields within the healthcare industry; some of which are discussed in this section.

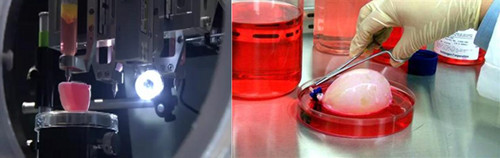

Organ and body tissue regeneration is an incredible ability observed in plants, vertebrates, and mammals. However, this ability is naturally very limited in humans Regenerative science is expected to provide replacement tissue and entire organs by applying tissue engineering which begins with living cells that are multiplied. The cells are seeded into a 3D containment structure that facilitates the directed 3D growth and proliferation while also providing nutrients to the cells.

Figure 8: Bio printing machine (left), Bio-printed model of Kidney (right) (7)

3D printing of human tissue and organs can revolutionize the healthcare industry by extending the average life expectancy and greatly improving the quality of life for millions of people. Organ recipients will no longer have to wait months or years for a donor with the correct blood type, organ transplant rejection will be abolished, illegal human trafficking for organ harvesting can be minimized, and war and accident amputees can once again gain full mobility. 3D Bio-printing may have unprecedented consequences on regenerative medicine and quality of life while minimizing ethical and religious issues which currently surround human embryo techniques.

Dental industry has been using artificial material for dentures, orthodontics, implants, crown, and bridges for many years. As these parts are custom made for each person, the process is both time consuming and expensive. Direct and indirect 3D printing, namely printing the actual part or a mold, has been shown to be a cheaper and faster alternative to conventional techniques.

Figure 9: Wax implant for indirect manufacturing (left), Co-Cr implant,

SLM direct manufacturing (right) (1)

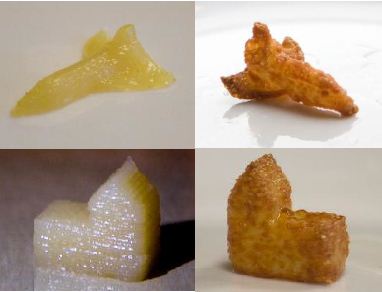

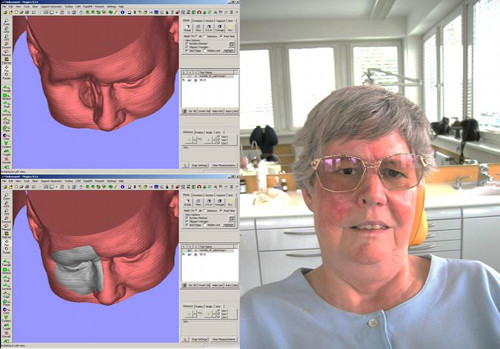

Becoming more integrated and secured implies improving life chances and providing people with equal opportunities. These opportunities may include the ability of human communication or mobility which is considerably difficult for people with various disabilities and illnesses such as considerable in disabilities cases like Arthrogryposis. Regarding this, 3D printing as an advanced technology can compensate the individual’s disability or deficiency by manufacturing complex composite 3D objects using 3D scanned data. It can help people regain mobility, improve their employment and social opportunities and possibly help self-reliance and alleviate self-confidence issues. As an example, a facial reconstruction surgery using a 3D printed eye bone is shown in the figure 11.

Figure 11: Scanned and designed CAD model (left), Integration due to 3D printed part (right) (1)

Self-actualization stands at the top of Maslow's hierarchy of needs. The basis form of the perceived need for self-actualization can be defined in a sentence, “What a man can be, he must be”. This level of need refers to a person’s potential and realizing that potential. Education and creativity as two important branches of self-actualization are reviewed in this section.

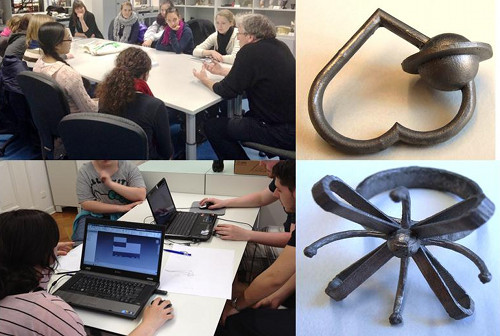

The education system plays an important role in aiding people achieve their full potential. 3D printing can revolutionize the learning experience by helping students interact with the subject matter. Affordable 3D printers in schools may be used for a variety of applications which can aid students in finding their field of interest easier and faster. Currently there are different types of educational projects in order to attract students to the various fields by giving them the opportunity to create and fabricate their own designs using 3D printing technology.

Figure 12: Students working on their own design using the 3D printing technology (left), Jewelry parts designed and printed by the students (right) (8)

The ability to develop and present ideas is one of the most important needs in the society and human development. Regarding this 3D printing can enable the creation of complex geometries which are very difficult, expensive, or impossible to be manufactured using conventional production methods. Figure 13 shows two such ordinary products which can design and customized as per customers’ demands.

Figure 13: Paris sandal (1), complicated ring geometry (9)

3D Printing technology could revolutionize and re-shape the world. Advances in 3D printing technology can significantly change and improve the way we manufacture products and produce goods worldwide. An object is scanned or designed with Computer Aided Design software, then sliced up into thin layers, which can then be printed out to form a solid three-dimensional product. As previously described, the importance of an invention can be appraised by determining which of the human needs it fulfills. As shown, 3D printing can have an application in almost all of the categories of human needs as described by Maslow. While it may not fill an empty unloved heart, it will provide companies and individuals fast and easy manufacturing in any size or scale limited only by their imagination. One of the main advantages of the industrialization revolution was that parts could be made nearly identically which meant they could be easily replaced without individual tailoring. 3D printing, on the other hand, can enable fast, reliable, and repeatable means of producing tailor-made products which can still be made inexpensively due to automation of processes and distribution of manufacturing needs. If the last industrial revolution brought us mass production and the advent of economies of scale - the digital 3D printing revolution could bring mass manufacturing back a full circle - to an era of mass personalization, and a return to individual craftsmanship.

1. Gebhardt, A., Understanding Additive Manufacturing, Hanser Publications (Cincinnati, 2011).

2. Maslow, A.H. (1943). "A Theory of Human Motivation, Psychological Review 50(4): 370-96.

4. Lipton, J.,et al, Multi-Material food printing whith complex internal structure suitable for conventional post processing, utexas 809-8015, (2010)

5. Khoshnevis, B. Experimental investigation of contour crafting using ceramic materials, Rapid Prototyping Journal, Vol. 7 Iss: 1 pp. 32 - 42, (2001)

6. http://www.rael-sanfratello.com/?p=916

7. Anthony Atala, Institute for Regenerative Medicine, TED conference

8. Fachhochschule Aachen university, Silber fuer Zukunft project

9. Jo-hayes award, http://www.johayes.com

Prof. Dr.-Ing. Andreas Gebhardt

Goethestraße 3

52064 Aachen

Email:

gebhardt@fh-aachen.de

Miranda Fateri, Master of Science

Goethestraße 3

52064 Aachen

Email:

fateri@fh-aachen.de