Untitled Document

© 2012 Jürgen Gausemeier; Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-33559

In the first study of the Heinz Nixdorf Institute and the Direct Manufacturing Research Center, “Thinking ahead the Future of Additive Manufacturing” 14 current application fields of AM were analyzed [1]. The analysis of the Business of Today indicates that AM is progressively gaining importance, as it opens up new opportunities in many instances, and that AM is progressively pushed from Rapid Prototyping towards small series production – the so called Direct Manufacturing. Various industries are seeking for ways how to capitalize on the benefits AM provides, such as the freedom of design. Today, AM is already widely spread within the medical sector, including dental applications, prostheses, implants etc. Progressively, AM-technologies are being applied within the capital goods industry, e.g. in the armament, automotive, electronics as well as in the tool- and mold-making industry. Even, consumer industries such as the sports, textile, furniture, toys or the jewelry industry are becoming aware of the great advantages of AM for their business [2], [3].

In particular the aerospace industry, which produces geometrically complex high-tech parts in small lot sizes, can benefit from AM’s flexibility and is therefore, already today in the vanguard of the industrial application of AM. In addition, research on increasing energy efficiency of aircrafts and reduction of air pollution and noise exposure promote the demand for particularly light-weight and high-strength parts with partially complex geometries [2], [4]. Additively manufactured parts increasingly meet these requirements and therefore progressively find their way into today's aircraft production [5].

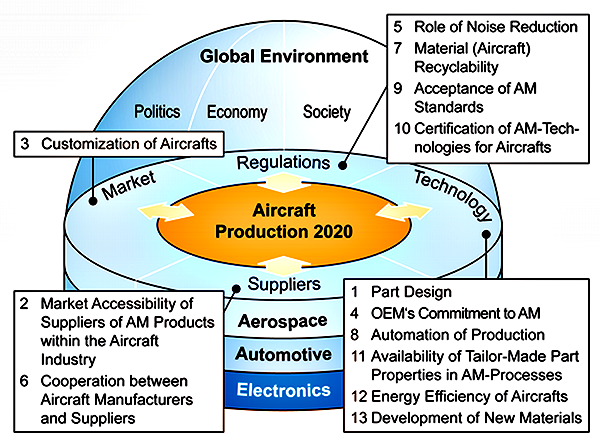

Based on the analysis of the Business of Today, the aerospace, automotive and electronics industry were outlined as particularly auspicious for the Business of Tomorrow of AM. For sustainable business success, the visionary insight into the future, the early identification of tomorrow’s success potentials and the timely exploitation of these potentials are indispensable. The scenario-technique is a suitable tool for that kind of systematic foresight and the detection of future success potentials. Using the scenario-technique, future (branch) scenarios for the aerospace, automotive and electronics industry for the year 2020 were developed, focusing the aircraft production, automotive production and the electronics industry manufacturing equipment, respectively, see figure 1. Scenarios are possible situations in the future, based on a complex network of influencing key factors, and cover the future Market Pull. For the aerospace industry, 13 key factors describe possible futures of the aircraft production, comprising statements on suppliers, market, branch technology and regulations, see figure 1. Thereby AM-technology providers get an idea of how the areas of application for their products may look like in future. As industries do not operate as standalone players, scenarios for the global environment were developed, comprising comprehensible statements on future developments of politics, economy, society and environment. Even though these developments cannot directly be influenced by the individual players in the market, they are of crucial importance for the Business of Tomorrow. Therefore, the branch and global scenarios were combined to consistent overall scenario combinations.

The most probable scenario combination with the highest effect on the focus of each considered industry was selected as reference scenario. Based on this, strategic directions for each industry were deduced. For the aerospace industry, the selected scenario combination describes a future, where Europe sets the pace in a globalized world. The aircraft production is characterized by individual customization of aircraft which fosters the application of AM-technologies. Due to the successful part implementation, additively manufactured parts start to be associated with high performance and high quality. To enhance the penetration of DM-technologies within the aircraft production, it will be necessary to build up general ground rules for the design of secondary aircraft structures, systems etc. for AM-technologies and to flow them down to suppliers [5].

Figure 1: Spheres of influence for the scenario development and key factors for the aircraft production

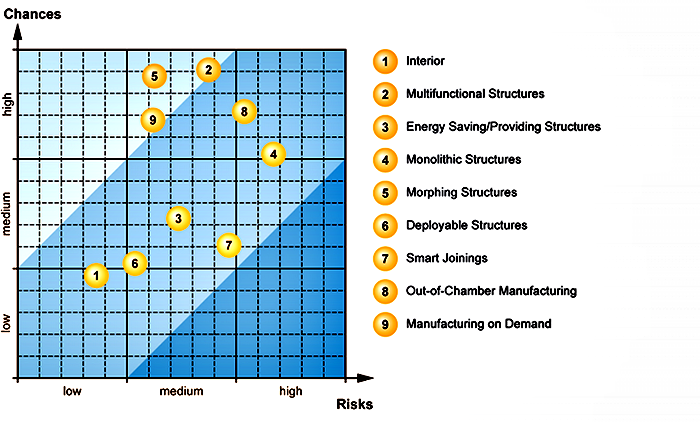

The developed scenarios describe how the production in the examined industries may look like in the future and show possible development paths for AM-technologies. Using the selected reference scenario combinations, creativity workshops with experts from the field of AM and the three industries were conducted to identify future applications of DM. The spectrum of the identified applications encompasses 120 ideas that were clustered to 27 innovation fields and prioritized based on the assessment of their chances and risks. A higher customer benefit provided through AM and a high market potential are possible chances, as these aspects enhance the attractiveness of an application idea. In contrast, a high degree of competition, high investments into research and development as well as a possible feasibility with conventional manufacturing technologies were taken into account as risks. Based on the assessment, each innovation field was positioned in a chances-risks-portfolio, as shown in figure 2. The ordinate intercept shows the chances; the abscissa intercept indicates the risks. For the aerospace industry, Morphing Structures and Multifunctional Structures have been identified as the most auspicious innovation fields for the application of DM:

-

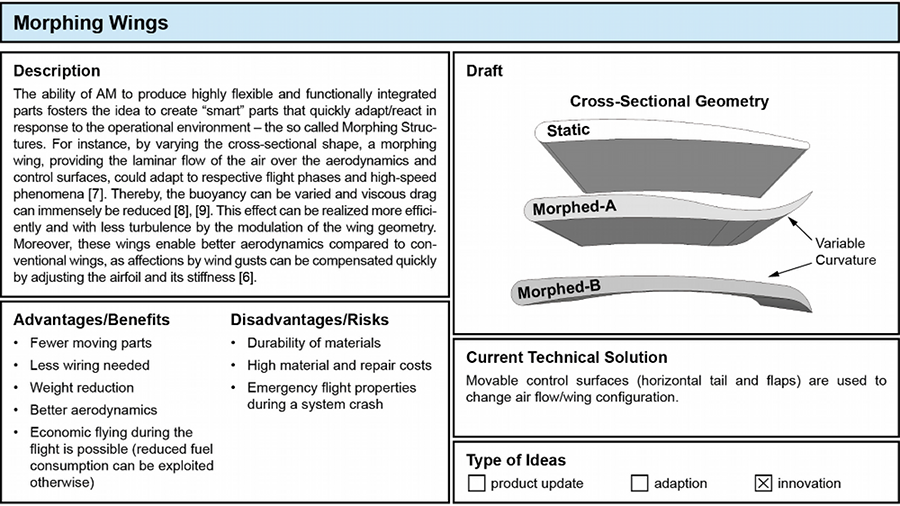

Morphing Structures describe parts which are designed as one part that is adaptable in its shape in response to the operational environment. Instead of changing the position of a static part by using actuators, the part itself can take continuous configurations of shape to enable specific functions. This can contribute to improve flight and to reduce fuel consumption.

Multifunctional Structures comprise ideas for functionally upgraded parts. Upgraded functionality can, for instance, be realized by integrating acoustic and thermal insulation into aircraft parts or by embedding entire sensor/actuator systems, including electronic wiring and connectors into a part. This can contribute to realize self-optimizing parts [6]

Figure 2: Prioritizing innovation fields of the aerospace industry using a chances-risks portfolio

Figure 3 exemplarily depicts the characteristics for the idea Morphing Wing from the innovation field Morphing Structures. These wings adapt to environmental conditions like wind, flight speed etc. and thereby significantly contribute to fuel savings [6].

Figure 3: Exemplary idea from the innovation field Morphing Structures: Morphing Wings

Highly prioritized application ideas are currently concretized through realization and implementation studies within specific workshops and through market research.

To enable AM-technologies for DM of the identified future applications, it is necessary to align the technology development with current and future requirements the applications impose on DM. This enables the AM-industry to develop and pursue consistent technology strategies and to bundle available competences to effectively advance AM-technology into dependable DM-technology. Therefore, the developed innovation fields were analyzed in detail to deduce requirements on DM [10].

First, general requirements were identified. General requirements are overall requirements that do not relate to a specific technology; they are rather related to the performance of a company and need to be fulfilled for being successful. Exemplary general requirements are high innovation ability, strong competences to provide solutions, strong consulting competences (Pre-Sales-Support) etc. In addition, technology-specific requirements were deduced from the innovation fields. For instance, a high process stability and certification of AM-processes and AM-parts are relevant for the vast majority of the innovation field across all three industries, especially for safety-critical parts. The provision of generally accepted design rules is a basic prerequisite for the most innovation fields, e.g. for the innovation field Morphing Structures, as their design is very complex and the functionality of those structures often depends on many parts that perfectly interact with each other. General design rules can also contribute to minimize costs and time effort for design. The processability of different materials with AM-machines is a requirement that is relevant for e.g. the Aircraft Interior and Morphing Structures, as the used materials range from magnesium to carbon-fiber-reinforced polymers [10].

To identify the most important general and technology-specific requirements and the performance of AM-technologies concerning the technology-specific requirements, the Heinz Nixdorf Institute and the Direct Manufacturing Research Center conducted an expert survey on current and future requirements on DM-technologies [11]. To reflect the opinion of the entire AM-industry, the survey addressed AM-experts along the whole value chain.

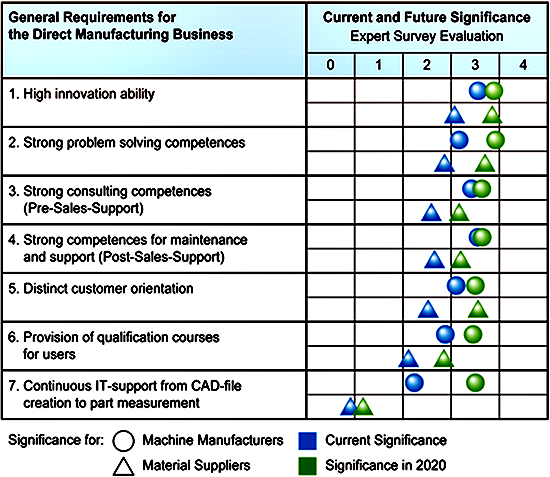

First, the survey asked the experts to judge the current and future significance of general requirements for the DM-industry on a scale from “0” to “4” (no significance up to high significance). In figure 4, for each general requirement, the average current (blue) and future significance (green) are visualized, differentiating the significance for machine manufacturers (bullets) and material suppliers (triangles). The overall assessment shows that the significance of the requirements will increase in future.

Figure 4: Current and future significance of general requirements for

machine manufacturers and material supplier

Additionally, all requirements will be more significant for machine manufacturers than for material suppliers. Today, high innovation ability has the highest significance for both and will be highly significant in the future. Strong problem solving competences currently have a relatively small significance, but its significance will significantly increase in the future for both groups.

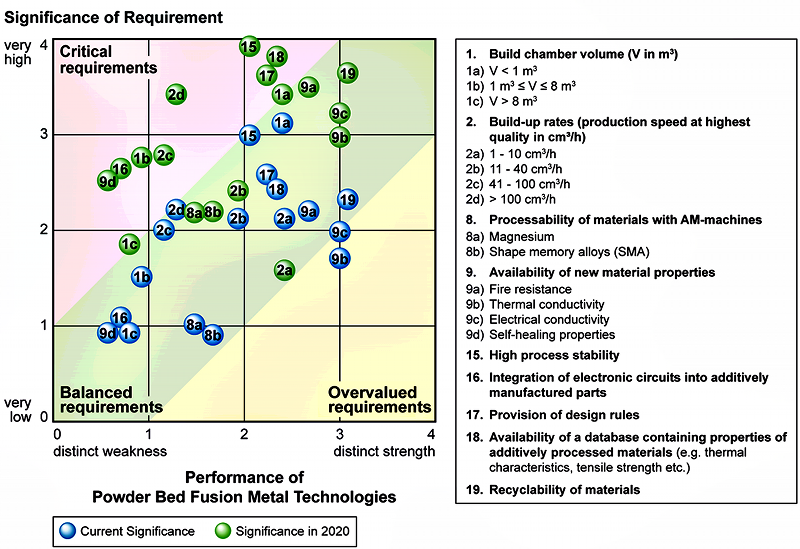

In a next step, the experts were asked to specify the significance of technology-specific requirement for the DM-industry from today’s point of view and its significance in 2020, using a scale from “0” to “4” (no significance up to high significance). In addition, the experts estimated each technology’s performance regarding each requirement (performance) on a scale from “0“ (i.e. there is a call for action) to “4“ (i.e. the technology has got a distinctive strength concerning this requirement). The overall assessment shows that their significance will increase in the future. Especially, high process stability, a database containing properties of AM-materials, on-line quality control processes, continuous certification and the provision of design rules are assessed to be outstanding requirements for the penetration of AM in the future. The requirements with the largest deviations between the current and future significance are the following:

-

Ability of AM-machines to process different types of materials within one job;

-

Building up on 3-D surfaces;

-

Provision of additively processable shape memory alloys;

-

Automated integration of AM-machines into existing production lines;

-

Highly integrated AM-machines.

For some requirements there are considerable discrepancies between their significance for the innovation fields and the experts’ assessment of the significance. For instance, larger build-chamber volumes are required for the realization of a large number of product ideas developed for the aerospace and automotive industry, such as morphing structures or functional body-in- white, respectively. However, according to the experts, a build chamber volume sized larger than 8 m3 is not expected to be significant in the future [10].

The significance of the technology-specific requirements largely correlates with the performance across of all considered technologies, as exemplarily shown in extracts for the performance of Powder Bed Fusion Metal Technologies in figure 5.

Figure 5: Excerpt from significance-performance portfolio for Powder Bed Fusion Metal Technologies

In the future, the vast majority of the requirements will gain in significance. Therefore, they are likely to turn into critical requirements if no technological advances will be achieved. Some requirements, such as build-up rates > 100 cm³/h (No. 2d) and high process stability (No. 15) of Powder Bed Fusion Metal Technologies, are judged as almost critical today and needs to be improved continuously. Therefore for instance, research that contributes to the production speed could promote AM-technologies in future. The amount of research that has to be conducted to meet a requirement sufficiently strongly depends on the individual technology. For example, an adequate availability of materials with self-healing properties requires much more effort in development, than increasing process stability to a sufficient level. In contrast, requirements like build chamber volume < 1 m³ are already matched comparably well and will, if at all, require only little efforts to suit future requirements [10].

The study “Thinking ahead the Future of Additive Manufacturing – Analysis of Promising Industries“ discloses opportunities for AM-technologies in the automotive, aerospace and electronics industry. Based on three scenarios, ideas for future applications of AM in the analyzed industries were developed. The requirements deduced from these ideas were assessed within an expert survey. The results were published in March 2012 in the study “Thinking ahead the Future of Additive Manufacturing – Future Applications“.

In future work, necessary advancements of existing DM-technologies with regard to the examined requirements will be outlined. This will cover the Technology Push. The result is an innovation roadmap indicating when the developed future applications can be manufactured as technological requirements will be fulfilled. This represents the synchronization of the Market Pull and Technology Push.

1. Gausemeier, J.; Echterhoff, N.; Kokoschka, M.; Wall, M.: Thinking ahead the Future of Additive Manufacturing – Analysis of Promising Industries. Study for the Direct Manufacturing Research Center, Paderborn, 2011

2. Bourell, D.; Leu, M.; Rosen, D.: Roadmap for Additive Manufacturing – Identifying the Future of Freeform Processing. The University of Texas, Austin, 2009

3. Wohlers, T.: Wohlers Report 2011 – Rapid Prototyping and Manufacturing State of the Industry. Wholers Associates Inc., United Stated of America, 2011

4. Bullinger, H. (Ed.): Technology Guide – Principles, Applications, Trends. Springer Verlag, Berlin, 2009

5. Workshop: Opportunities and Barriers of DM Technologies for the Aerospace Industry and adapted others. Paderborn, October 2010

6. Workshop: Idea Creation for DM-Applications in the Aerospace Industry. St. Louis, MO, May 2011

7. Weisshaar, T. A.: Morphing Aircraft Technology – New Shapes for Aircraft Design. Aeronautics and Astronautics Department Purdue University, 2006. Under: http://www.dtic.mil/cgi-bin/Get TRDoc?AD=ADA479821, Accessed in December 2011

8. Haydock, H.; Kollamthodi, S.; Falconer, A.: EU Transport GHG: Routes to 2050 – Energy security and the transport sector. Didcot, UK, June 2010

9. Nathan, S.: Composite Class: Developing the Airbus A350-XWB. In: The Engineer Online. London, UK Under: http://www.theengineer.co.uk/in-depth/the-big-story/composite-class-developing-the-airbusa350-xw b/1009059.article, Accessed on January 2012

10. Gausemeier, J.; Echterhoff, N.; Kokoschka, M.; Wall, M.: Thinking ahead the Future of Additive Manufacturing – Future Applications. Study for the Direct Manufacturing Research Center, Paderborn, 2012

Prof. Dr.-Ing. Jürgen Gausemeier

Heinz Nixdorf Institute, University of Paderborn

Fürstenallee 11

33102 Paderborn

E-Mail:

Juergen.Gausemeier@hni.upb.de

WEB:

http://www.hni.uni-paderborn.de/pe/

Dipl.-Wirt.-Ing. Niklas Echterhoff

Heinz Nixdorf Institute, University of Paderborn

Fürstenallee 11

33102 Paderborn

E-Mail:

Niklas.Echterhoff@hni.uni-paderborn.de

WEB:

http://www.hni.uni-paderborn.de/pe/

Dipl.-Wirt.-Ing. Marina Wall

Heinz Nixdorf Institute, University of Paderborn

Fürstenallee 11

33102 Paderborn

E-Mail:

Marina.Wall@hni.uni-paderborn.de

WEB: http://www.hni.uni-paderborn.de/pe/