Sonderpublikation:

Printer, Fabber und Co.

Spielzeug oder Revolution?

Rapid Prototyping erreicht den privaten Nutzer Der Markt der Generativen Fertigungsanlagen (auch Rapid Prototyping Anlagen genannt) erweitert sich mit großer Geschwindigkeit hin zu kleinen und preiswerten Anlagen. So sind in den vergangenen 2 Jahren über 10 Systeme vorgestellt worden, die im Preissegment um und unter 10 000 €, rangieren oder dieses zum Ziel haben. Daneben etablieren sich Bausätze und Selbstbausysteme deren Preise bei unter € 1000 beginnen. Durch Internet-Blogs begleitete Bewegungen wie Fab-at-Home und eine Sammelbezeichnung dieser Maschinen als „Personal Fabricator“, „Personal Fabber“ oder einfach „Fabber“ unterstreichen, dass sich mit privaten Nutzer eine neue Anwendergruppe und ein Massenmarkt etabliert. Spätestens mit der Vorstellung des 3D Druckers HP Design Jet (einer mit HP Logo versehenen Dimension u-Print) ist das Anfang Mai 2010 einer breiteren Öffentlichkeit bewusst geworden. Dies kommt einem Paradigmenwechsel gleich. Jedermann bedient seine Anlage und löst die bisherigen Spezialisten ab, die Anlagen stehen in jedem (Kinder) Zimmer, der Vertrieb erfolgt über das Internet. Der Kunde konzipiert und produziert sein eigenes Produkt. Welche Ergebnisse sind zu erwarten? Was können die kleinen, billigen und einfach zu bedienenden Anlagen? Wie schnell sind sie? Welch Art von Bauteilen fertigen sie? Mit welcher Genauigkeit? Was kosten die Materialien? Sind sie haltbar? Wer hält die Maschinen instand, wer repariert sie? Was kosten Reparaturen? Um Sie an dieser Entwicklung teilhaben zu lassen, haben wir uns entschlossen, Beiträge zum Fabbing und über die Fabber in das RTeJournal aufzunehmen. Da es sich hierbei nicht um Peer-reviewte Artikel handelt, stellen wir diesen Beiträgen diesen gemeinsamen Text voran um diese als solche auszuweisen.

Ich wünsche Ihnen viel Spaß bei der Lektüre

Ihr

Andreas Gebhardt

Breaking Down Barriers — The Democratisation of 3D Digital Technologies for Design and Manufacturing

© 2010 Martin Stevens; Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-28436

Abstract

The price and accessibility of advanced technologies for product development and manufacturing have long been the greatest barriers to unlocking the widespread uptake of the technologies. Those barriers have now categorically been removed. However, the perception that they still exist remains prevalent and it is only through the fervent efforts of companies such as A1 Technologies that this perception is gradually being overcome.

There are two common misconceptions associated with the field of design and manufacturing, namely that the discipline demands large capital investment and significant skill levels that require years of training. In no way is this comment intended to disparage the investment and the skill levels essential for certain sectors of industry — aerospace, medical equipment and automotive to name just a few — where precision equipment together with knowledge and experience is vital. However, that said, it is not necessary to have years of technological know-how to develop new applications using advanced 3D technologies and processes. Furthermore, the technologies involved in designing in three dimensions, creating 3D data using advanced 3D laser scanning techniques and producing 3D models and products using additive manufacturing processes do not have to cost a fortune. It is pertinent to mention that these misconceptions exist now because for many years they were true but the market landscape has changed dramatically in the last 12 months.

A1 Technologies is one company that is largely responsible for changing the landscape and is now fighting hard to overcome the existing misconceptions. As a result, the message is now penetrating through to a wider audience. With a portfolio of ultra low-cost products that covers every aspect of 3D digital design and manufacture, A1 can readily demonstrate how advanced digital 3D technologies can be both affordable and usable by anyone. What is more, the products that A1 Technologies offer can all be integrated to provide a comprehensive and compelling product development solution that is accessible to anyone.

The global manufacturing industry is vast and complex, and, in general, advanced design and manufacturing technologies have been the dominion of specialized manufacturing companies with expensive specialist equipment to create and produce products to meet demand. There has, of course, always been the odd exception to the rule, with entrepreneurs striving and sometimes succeeding against the odds.

From the largest multi-national organisation down to a single factory outlet, the business model for manufacturing companies is typically structured in a standard way. This traditional structure is facing a significant challenge to the status quo, however, and accessible, low-cost 3D digital technologies are a predominant reason why.

There is an emerging trend that points towards personalised manufacturing.

For some years, visionaries have forecast a future when people from any walk of life will design and make what they want, when they want it, with 3D data and 3D printers being an everyday commodity. As stated in the introduction, until recently the prohibitive price tag of 3D digital technologies — 3D CAD software, 3D printers and 3D scanners — has been one of the greatest barriers preventing this vision from becoming a reality. However, the recent emergence of fully capable, low-cost 3D design packages, 3D printers and 3D laser scanners have literally demolished this barrier.

An interesting development in recent months is a term that has become fairly common on the 3D printing blog circuit, namely the ‘hobbyist’. In broad brushstrokes the ‘hobbyist’ refers to an increasing number of entrepreneurial users of low-end 3D printers that have previously been unable to experiment and develop with the technology due to the stated prohibitive barriers. It is not great terminology because ‘hobbyist’ does not convey the potential of these individuals or their use of the machines in a global context for industrial development or for widespread adoption as a means of local manufacture. That said, it does point to an increasing number of users testing and trialing 3D printing equipment for new and unique applications. The creative sector is a notable case in point here — a sector that is positively contributing to the evolution of the personalised manufacturing trend and one that, to date, has often been inhibited by the capital cost of equipment or the complexity of 3D CAD.

An outstanding interim solution to the notion of local manufacturing is the Fab Lab concept, which has succeeded in demonstrating how this trend could realistically move forward. Originating as an outreach programme run by the Centre for Bits and Atoms at MIT, the Fab Lab concept has grown at an unprecedented rate with a network of labs that now span the whole globe. The first Fab Lab in Germany was recently established in Aachen, with more German Fab Labs under development which are expected to open in the near future.

The basic concept of a single Fab Lab is to provide a community technical centre housing a range of digital fabrication equipment costing in the region of $50,000. The motivation is to provide an environment that is open and accessible to anyone —permitting technological empowerment and hands-on technical training for people that may never otherwise come into contact with such capability. Proven results are the ability of local people to identify, design and produce solutions to local problems and small-scale high-tech business incubation from grass-roots research. Obviously, the capital cost of equipment and its accessibility in terms of ease-of-use and safety are two of the major factors in the provision of equipment in a Fab Lab. With a portfolio of products that meet these needs precisely, A1 is actively exploring the potential of working with the Fab Lab team to provide a range of interoperable and accessible 3D digital solutions for designing, laser scanning and manufacturing.

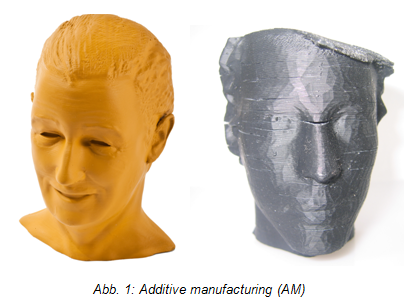

Additive manufacturing (AM) technology has proved to be disruptive and offers many advantages to manufacturing companies that now make use of it — reduced development time, reduced development costs, much faster time-to-market overall and greater design freedom are just some of the demonstrable benefits when the technology is integrated well into the manufacturing process. Continuing improvements to the technology have seen it exceed many of the original expectations with additive processes now being used as a final production method for some applications.

All additive processes are based on the same principle — building parts additively, layer by layer, at the sub-millimetre scale. This is a very different approach to manufacturing parts and/or prototypes, when compared with the traditional methods of milling, moulding, casting or machining. The origins of the technology go back to Rapid Prototyping, which emerged in the late 1980’s, and offered a revolutionary way to create prototypes that could be used for concept generation. Subsequent developments in the processes themselves and the materials that can be used have seen huge improvements in prototyping capability, allowing users to test the form, fit and function of their products as well as the emergence of a host of new applications such as rapid tooling, rapid casting, and the final production of end use parts — additive manufacturing.

As a result of the developments and growth of the additive manufacturing market it has now fragmented somewhat, with two specific focus areas — processes that are dedicated to prototypes to radically improve product development and stimulate concept innovation and processes dedicated to manufacturing and directly producing complex, repeatable components and products. Today, the term 3D Printing typically covers the prototyping market and additive manufacturing refers to processes used for production, but universally accepted terminology is still elusive.

These advanced additive technologies have long been associated with only the largest and most cash-rich companies because typically, process acquisition required a hefty capital investment. Mid-range 3D printers cost in the region of £30,000; while entry level 3D printers have generally been around the £10,000–15,000 mark. Throughout 2008 and much of 2009 there was a great deal of talk about the emergence of a sub-£5000 printer — a target that many commentators suggested would make 3D printing much more accessible to smaller companies and to individuals. That target has been met — and exceeded — because last year A1 Technologies launched the RapMan 3D printer, a competitive, entry-level platform that is available in kit form for under €1,000 as well as a ready-built, sturdier platform, the BfB 3D 3000, for under €2,500.

Here is the crux of the matter, there is now a 3D printer available that offers good capability, at a price that virtually any company, school and many individuals can consider. Moreover, the printing materials that the platform uses are easily sourced, inexpensive and completely safe. The two ideal polymers for use with the RapMan and with the BfB 3D 3000 are ABS and PLA. ABS (Acrylonitrile Butadiene Styrene) is a strong and rigid material with many industrial applications, including internal car parts such as dashboards. The material can be supplied in six different colours. Parts and models built on these 3D printers in this material can be easily post-processed (painted, plated, glued and screwed) to achieve any desired effect. The other key material is PLA (Poly Lactic Acid); PLA is a bio-polymer made from potato starch and is therefore biodegradable. It comes in four translucent colours and is ideal for printing large models, which can be up to 200 mm in each direction. The polymers cost between £40 and £50 per kilo.

Since its launch, the reaction to the BfB RapMan has been mixed — until people actually see it working, at which point the unanimous verdict is one of awe and amazement at the quality of part that is produced. Prior to seeing this 3D printer, ironically, it is the price that seems to generate skepticism. Another problem is that the RapMan has been confused, both in the press and in general debate, with some of the (excellent) open source channels for developing 3D printers. The RapMan is a fully commercialized 3D printing platform.

Actually producing a part on a 3D printer is only a small part of the whole process. Designing the part for manufacture and producing the 3D data necessary to do so is of equal importance. There is a proliferation of 3D CAD packages available with varying degrees of capability, price tags and product support for designing products in 3D. Moreover, there has been much debate concerning the functionality associated with 3D CAD — what is necessary and what is hype — and even experienced users can find the 3D CAD interface restrictive. A conservative estimate would classify the source of more than 90% of all 3D designs as 3D CAD. However, the more interesting statistic to consider is the proportion of 3D CAD users in the context of the potential population that could or would design 3D models with accessible, easy to use, low-cost 3D design software. A tiny fraction.

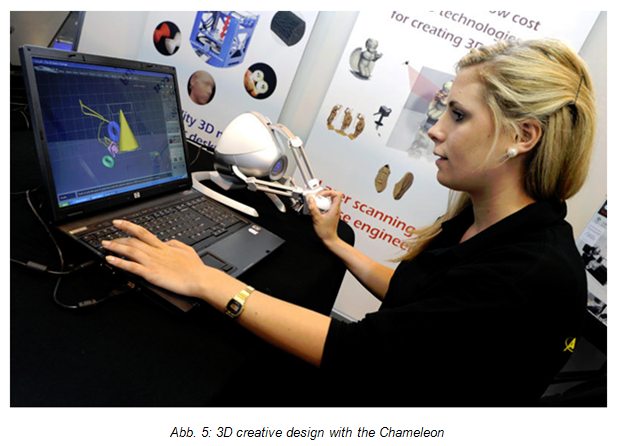

This is another area where A1 Technologies seeks to provide a functional and capable alternative. The company’s 3D ‘haptic’ application, Chameleon, delivers a high quality, immersive 3D experience to its users facilitating greater efficiency when working, designing, creating, training — or simply just playing — in virtual 3D space. The Chameleon package incorporates Anarkik3D’s Cloud9 software — a 3D sketch/modelling software suite — that enables easy and fluid conceptualisation and visualisation of ideas. The software is easy to learn and fully interactive and has demonstrable appeal to experienced CAD users and non-users alike. What sets Chameleon apart further is that it uses new touch-enabling technology, which replaces the traditional 2D mouse. This haptic device is a 3D mouse, which provides users with a more natural interaction within three-dimensional virtual space and allows significantly more intuitive working.

Chameleon allows anyone — of any age — to be creative by constructing 3D objects, particularly free-form shapes, within the software, often unlocking latent talent that would otherwise remain undiscovered. Unlike 3D CAD which, with its large number of functions and layers of complexity takes time to learn and requires regular use to remember, the Chameleon can be learned within an hour and is easy to use. When complete the models can be directly and easily 3D printed. Accessible thanks to its ease of use, it is equally accessible in terms of price, as it is available for only €600.

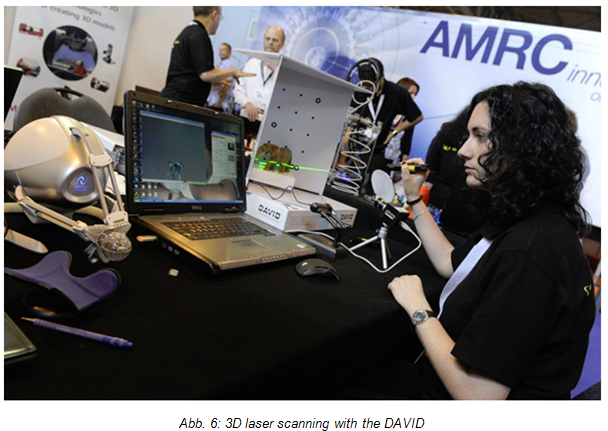

As stated, 3D data is often now a prerequisite for product development. Many products also have to undergo re-development but existing data only exists in 2D. Today, the easiest way to acquire 3D data for such models is to scan the original and modify or upgrade the resulting 3D model - often referred to as reverse engineering. The discipline of 3D laser scanning in many ways mirrors that of 3D printing, with the price of the equipment traditionally being restrictively high. This is another area where A1 Technologies is able to provide a quality, high-value, low-cost alternative. An element of A1 Technologies portfolio is the DAVID-laserscanner - a very low-cost system for contact-free scanning of 3D objects. The only hardware requirements are a hand-held laser and a camera and the full kit comprises a webcam; a red line laser module (650 nm, Class 1 laser) with adjustable focus, including battery; calibration panels (for three different object sizes); a base plate for mounting the calibration panels; DAVID-laserscanner Professional Edition software on a USB Flash Drive; a stand for the webcam; and a full user manual. Once again, ease-of-use comes as standard and the DAVID-laserscanner is capable of producing 3D data that can be used in various standard file formats. To obtain the required data users simply hold the laser in their hand and sweep the laser line over the object to be scanned. The DAVID-laserscanner will immediately generate a 3D model on a connected PC, capturing even fine surface details of less than 0.2 mm. With DAVID-Shapefusion it is possible to merge multiple scans that were made from different sensor directions in order to get a complete, textured 360˚ model.

Reverse engineering is just one application area — the data generated by the DAVID-laserscanner can be used for a host of other applications too, including computer animations, games, virtual 3D environments, product presentations, works of art and archaeology. The potential is limitless.

The lasers provided in the DAVID-laserscanner starter-kit are very low power and have therefore been designated completely safe for use (Class 1) in virtually any environment — even in an office.

Bringing together a range of products that complement each other so well and that can be used in conjunction with each other is a primary strategy of A1 Technologies in its bid to prove that high-calibre advanced technologies are accessible for anyone and everyone. The company is able to offer a full package or individual products in a way that will meet the needs of any product development process.

A full suite of design and manufacturing equipment can be purchased from A1 Technologies for under €2,000. This is phenomenal. Moreover, with recognized capability, this suite of products includes Chameleon; the David 3D laserscanner for capturing 3D data; and the RapMan 3D printer. The company can also supply a ready-built 3D printer, the BfB 3D 3000, at the extremely competitive price of €2,400.

Martin Stevens

Tel.: +44 (0) 777 565 1028

Email:

info@a1-tech.co.uk

WEB:

www.a1-tech.co.uk