Properties comparison of Injected and SLS material

© 2010 Asunción Martínez; Lizenznehmer RTejournal, weitere Informationen sind zu finden unter: http://www.dipp.nrw.de/service/dppl/

urn:nbn:de:0009-2-24125

Abstract

Most of the plastic injection companies are focused in the production of some products with a high exigency standard levels. That is why, to compete and gain some market share in front of the concurrency of companies from other countries, they need to be able to introduce new rapid prototyping techniques and product development.

The current rapid prototyping technologies as the Selective Laser Sintering (SLS) allow to obtain prototype pieces in a very short term (1 day), with a different range of materials. Between all these materials, the poliamide (nylon) with or without fiberglass are included in the list of the most used due to their excelent mechanical and resistance properties, they do not suffer against impact breakage, they do not deteriorate under extreme conditions of stress, temperautre and humidity, they are watertight (they are appropriate to use as a liquid container), etc.

To validate the functional prototypes obtained by SLS, AIJU has carried out an study of the materials used by this prototyping technology and has compared its behaviour with the aim to validate the pieces obtained by SLS in comparison with the commercially produced by means of injection with Sinterstation 2500 System.

It has been employed a commercial poliamide 12 (PA 12), Rilsan A, without charge and containing a 30% of fiberglass and a sintered PA12.

It was obtained standard tube to undertake mechanical test. It was also undertaken the characterization thermal and mechanical properties of the materials.

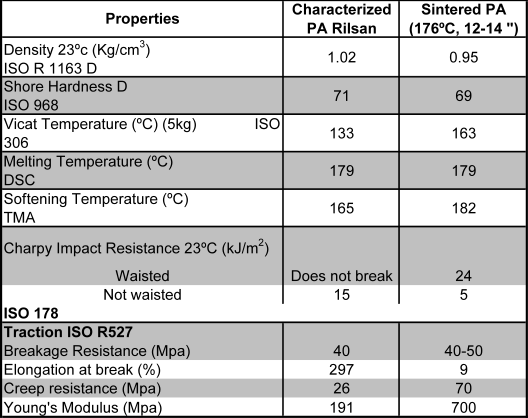

Table 1 incudes the results obtained with the PA without additional charge. The results showed that the density of the sintered PA is slightly inferior, but hardness is similar. The melting temperature are the same as it is the same material PA12.

The sintered PA keeps better the temperature as can be guessed from the higher values obtained in the Vicat temperature tests and the softening temperature. The sintered material is also stiffer as the Young Module and the creep resistance are higher. Nevertheless, the impact resistance and the elongation at break are inferior, although the breakage resistance is similar.

The sintered PA with fiberglass is

less rigid as the Young’s modulus

obtained is smaller. And the

mechanical properties are inferior

as determined by the values of

impact resistance, tensile strength

and the elongation at break point.

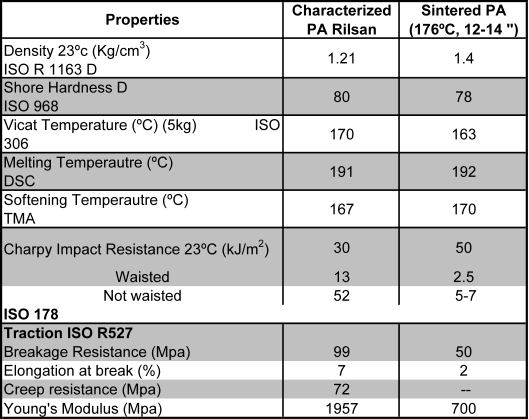

The results obtained with the polyamide with fiberglass are included in Table 2. The density of the sintered material is slightly higher as state the results obtained by thermogravimetric analysis, this material contains a 50% of fiberglass, nevertheless the hardness is similar.

Also the melting temperature is the same, as it is PA 12, as well as the Vicat and thesoftening temperature by thermomechanical analysis.

The sintered PA with fiberglass is less stiff as the obtained Young module is inferior. And the mechanical properties become inferior as it is obtained from the impact strength values, tensile strengthand the elongation at breaking point.

Thus, it is observed that pieces obtained by sinterization generally demonstrate good properties, comparing them with the achieved by means of injection, emphasizing its higher thermal resistance and inferior behaviour regarding the impact resistance. In the PA with fiberglass case the mechanical properties are slightly inferior to the obtained by means of injection, nevertheless the values obtained are useful for the selection of one or other material at the time of obtaining a functional prototype for a concrete use.

Table 1. PA without charge materials’ properties

Table 2. Propiedades de los materiales de PA con 30% de fibra de vidrio

Mrs. Asunción Martínez

AIJU - Technological Institute for Toys

Avda. de la Industria, 23

Email:

proyectos@aiju.info

WEB:

www.aiju.info